A well thought-out design is the basis for every new building. When designing it is the art of the architect to find the ideal solution together with the constructor in the field of tension between logistics, design and construction price. A good design therefore determines the sustainability of your project.

The Van Sluisveld Group works together with architects, engineers, contractorts and end-users to optimize the process from design to production and realization. By forming a construction team early in the construction process, the various disciplines can be coordinated to ultimately build an optimal building in price and quality.

Because the Van Sluisveld Groep also has the necessary constructive and architectural experience in-house, we also offer the possibility to take control of the entire process, from design to delivery.

A very important part of every construction is the structural design. For example, the construction must not only be able to bear the contents and the shell of the building, but also has to be resistant to external loads such as wind and precipitation, but also more extreme cases such as hurricanes, earthquakes and fire. In addition to these forces, the costs and the integration into the design are just as important.

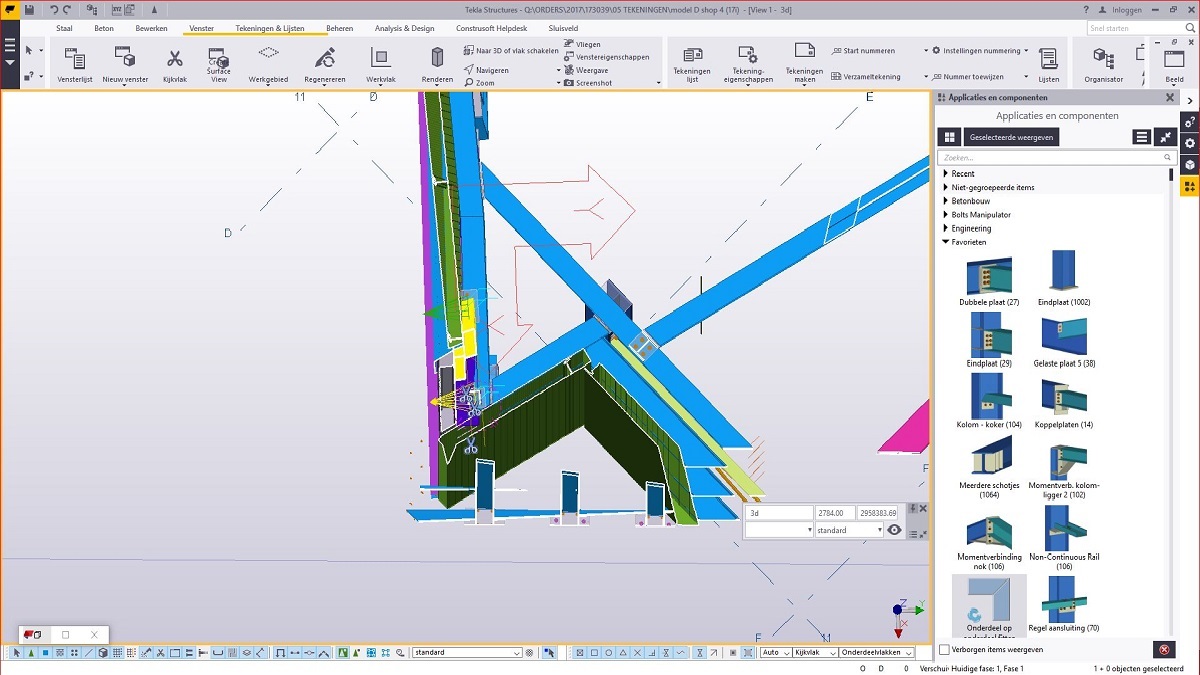

The team of the Van Sluisveld Group consists of experienced drafters and engineers, who develop the design in 3D according to national and international standards. Not only the bearing construction, but also the finishes are modeled in 3D.

In collaboration with the third party engineers, 3D models are exchanged, in order to look directly at possible cost-saving measures in such a way that an optimal price and quality ratio is created.

The Van Sluisveld Group uses the BIM software package Tekla, which makes it possible to exchange information between different parties in the construction team. In this way any bottlenecks can already be detected during the preparation process and be remedied for the execution. This possibility not only contributes to the lower construction costs, but also has a positive effect on construction time and quality.

The production hall of the Van Sluisveld Group is efficiently designed for the production process and equipped with a modern machine park.

After the steel profiles are delivered, they are initially stored inside the hall. At the start of the production process, the profiles are transported with overhead cranes, after which they first are cut to size and provided with the necessary penetrations and holes. This is done through a fully automated drill-saw and marking system where the steel beams are sawn, drilled, routed and marked according to the drawings or models.

With the help of our cambering machine, we can camber all steel beams which are available, a HE1000M will not make us think twice.

The required head, foot and sketch plates are manufactured by means of a CNC-controlled punching / shearing machine. Once these are ready, they are processed in accordance with NEN 3834-2 by our certified welders under the guidance of our welding coordinator(IWT).

As soon as the products are ready for preservation, they are provided with a wet paint system or hot dip galvanized and / or powder coated if required.

The Van Sluisveld Group offers various preservation options such as wet paints, powder coating and hot dip galvanizing or a combination of these.

If no aesthetic requirements are imposed or when the steel parts remain out of sight, red oxide prime can be applied. It is also possible to use a zinc phosphate primer, which is available in all common RAL colors. Both systems are a durable base for protecting a metal surface against rust and are applied in our production hall by means of a wet paint system.

The Van Sluisveld Group blasts steel and applies wet paint systems inhouse. In this way the paint is always applied to freshly blasted steel. Because the whole process takes place under one roof, there is no chance of rust formation and contamination, the paint system has an optimal adhesion and a guaranteed long life quality. We process coatings from the various suppliers in different systems in all preservation classes.

For outdoor applications or where steel comes into contact with a more aggressive climate, it is advisable to thermally galvanize the material. With hot-dip galvanizing, the entire steel parts are immersed in a large bath with molten zinc after a number of pre-treatment baths. A closed alloy layer will then form around the steel part, which provides excellent and long-lasting protection against an aggressive climate.

A combination of hot-dip galvanizing and wet coating or powder coating is also possible, the parts are deburred after the galvanizing process and the surface is roughened. Then a layer of wet paint or powder coat is placed over the galvanized part in any desired RAL color. This system is also called a Duplex Coating and is often used for visual work in an aggressive climate such as on the coast.

The Van Sluisveld Group offers both national and international transport and assembly for the products they deliver. By international and mainly overseas transport, logistical planning and handling are of great importance. The challenge is in keeping the transport costs as low as possible and delivering within the agreed deadlines. Efficient loading of the sea containers has become a specialty of the Van Sluisveld Group. Thanks to a self-developed loading system, it is often possible to use the entire contents of the containers, reducing the total number of containers to be used, which results in transport cost savings. Thanks to our loading system, we can load cargo safely and sea ready outside the container, without any damage.

For international transport, the Van Sluisveld Group works together with reliable transport companies with agencies all over the world.

Our products are installed by the experienced installers of the Van Sluisveld Groep at the request of the principal. In overseas projects, there is often a collaboration with a local party that carries out the assembly on behalf of the Van Sluisveld Group under the supervision and cooperation of 1 or 2 installers from the Van Sluisveld Group.

For specific products, such as Alkor Bright roofing from Renolit, it is imperative that these are installed by certified roofing workers, so that the manufacturer’s guarantee remains applicable. When the Van Sluisveld Group offers these products under warranty, installation of these products will also be included in the offer.

The Van Sluisveld Group has its origins in ship construction and still carries out activities related to this sector.

One of these activities is the forming of steel sheets by means of ship’s hulls, offshore constructions and civil works. The plates are formed in the right angle and shape tailored to the wishes of the client.

The roll and stamp presses are suitable for larger dimensions up to 3 meters in width. The roller press can press up to 200 tons and the stamp press up to 500 tons.

Besides regular steel, we also press stainless steel and aluminium.

Of course you can contact us without obligation to discuss the possibilities or to request a suitable quotation.

From preliminary design to key transfer, the Van Sluisveld Groep offers the possibility to take care of all steps with a complete building package.

We are your point of contact from start to finish and take care of the design, production, assembly and delivery. During all phases you will continue to be the principal in the decision-making process and involved in the progress of the project.

The Van Sluisveld Group carries out the following activities under the Complete Bulding Package:

• Design

• License applications

• Engineering

• Production

• Coordination and supervision

• Performance

• Delivery

• Aftercare

The work relates to the complete realization of the hull building with outer shell, possibly supplemented with internal walls.

With international projects, Van Sluisveld Groep works with local reliable parties, often with a long-standing relationship, the responsibility remains with the Van Sluisveld Group and is your permanent point of contact throughout the entire project.

By transferring the entire process to the Van Sluisveld Group, the various steps and components to be taken are efficiently coordinated, which benefits the total construction time and project costs

Holland West Indies Trading B.V., part of the Van Sluisveld Group, is a trading company that specializes in supplying construction materials to overseas territories, including the former Netherlands Antilles, Aruba and Suriname.

We can also be of service with aluminum parts such as windows, doors, window frames, curtain walls, all types of glazing, cassette facades, balcony fences, balustrades, rolling shutters and rolling grilles. The quality is guaranteed by the various dealerships of high-quality aluminum products, such as Shuco, Alcoa, SAPA and Horizal for the aluminum balcony systems.

Besides above manufacturers, we have developed our own sliding door system, which is specifically dedicated to the Caribbean areas. The SLS is a robust and maintenance free sliding door which is very applicable in hurricane areas.

Of course we can take care of the complete assembly of all products delivered by us. Our experience extends both at home and abroad.

Nederlands

Nederlands English

English